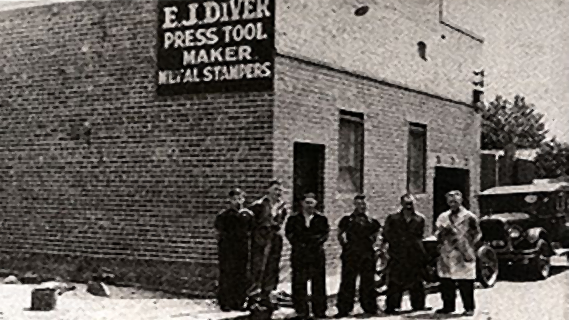

Mr. EJ Diver founded the business that has now grown to become Diver Consolidated Industries (DCI) in 1932.

EJ Diver & Staff commenced operating in a small factory in the inner Melbourne suburb of Carlton. The company's early beginnings were in press tool making and metal stamping activities, and it was in 1948 that Mr. Diver commenced supplying products to Holden, for the 48-215 (FX). This became the start of a long and successful business relationship with the Australian Automotive Industry.

Mr. EJ Diver founded the business that has now grown to become

Diver Consolidated Industries (DCI).

EJ Diver & Staff commenced operating in a small factory in the inner Melbourne suburb of Carlton in the early 1930’s. The company's early beginnings were in press tool making and metal stamping activities, and it was in 1948 that Mr. Eddy Diver commenced supplying products to Holden, for the 48-215 (“FX”) Holden. This was to become the start of a long and successful business relationship with the Australian Automotive Industry.

As the business grew, so did the need to acquire more space leading to DCI's first relocation, from Carlton to Preston, in 1964. It was at this time that Mr. Diver's son, Ted, became more actively involved in the running of the firm. Increased business activity and the blossoming relationship with the automotive industry necessitated the first of DCI's major expansions in 1974 when land and a building were purchased in the (then) Melbourne outer suburb of West Heidelberg.

In 1980, in direct response to the needs of the automotive industry, DCI invested in its first cold heading machines for the manufacture of steel fasteners. DCI's fastener business grew so quickly that in 1989 the fastener operations were relocated into their own facility in Thomastown.

Meanwhile, at West Heidelberg, DCI's Metal Stamping Division also continued to expand with its manufacturing activities now including component assemblies and robotic MIG welding. Once again growth saw DCI relocate its Head Office and Metal Stamping Division from West Heidelberg to Reservoir in 1994.

By 1996 automotive instrument panel cross car beams had been added to DCI’s product line-up. Our expertise making these very complex and important fabricated assemblies has continued to evolve so that today DCI produces all the IP beams purchased by Ford and Holden in Australia.

In 1996 DCI also commenced manufacturing specialty heat shielding materials using exclusively licensed technology from the USA. In time the success of this new product range, the development of our own materials and changing market conditions would lead to the eventual closure of DCI’s Thomastown Fastener Division in 2005 and it’s re-development as a dedicated Thermal and Acoustic Products manufacturing plant the following year.

Today DCI still operates two divisions, Metal Stamping and Head Office in Reservoir and the Thermal and Acoustic Products Division in Thomastown with a product line-up that has continued to expand.

DCI now produces not only automotive components for the Australian OEM market, but also exports to car manufacturers in Canada, the USA, China and South Africa. We make a variety of non-automotive products including the Triton range of wood working machines, the Retract-a-Steps range of safety access steps and our own “DCI Performance Products” range of aftermarket heat shielding products and accessories.

We remain a progressive market leader producing the highest quality products with a strong focus on customer satisfaction and technology. DCI is Dependable, Competitive and Innovative.

Premium Australian Heat & Sound Shielding

Premium Australian Heat & Sound Shielding